The predetermined overhead rate is set at the beginning of the year and is calculated as the estimated (budgeted) overhead costs for the year divided by the estimated (budgeted) level of activity for the year. This activity base is often direct labor hours, direct labor costs, or machine hours. Once a company determines the overhead rate, it determines the overhead rate per unit and adds the overhead per unit cost to the direct material and direct labor costs for the product to find the total cost. As you’ve learned, understanding the cost needed to manufacture a product is critical to making many management decisions (Figure 6.2).

Advantage of using pre-determined overheads

Overheads have been absorbed in the product cost traditionally using machine and labour hours. However, modern absorption requires the use of multiple bases to enhance the accuracy of the process. Further, the use of sophisticated techniques like the ABC costing system helps enhance the overall accuracy of the predetermined overhead rate example costing, quotation, and pricing. Overhead expenses are generally fixed costs, meaning they’re incurred whether or not a factory produces a single item or a retail store sells a single product. Fixed costs would include building or office space rent, utilities, insurance, supplies, and maintenance and repair.

1: Calculate Predetermined Overhead and Total Cost under the Traditional Allocation Method

- Therefore, the JKL’s predetermined manufacturing overhead rate for the new year will be $60 ($1,200,000/20,000) per production machine hour.

- As a result, two identical jobs, one completed in the winter and one completed in the spring, would be assigned different manufacturing overhead costs.

- Once a company has determined the overhead, it must establish how to allocate the cost.

- Overhead costs are expenses that are not directly tied to production such as the cost of the corporate office.

- Our work has been directly cited by organizations including Entrepreneur, Business Insider, Investopedia, Forbes, CNBC, and many others.

Then, they’ll need to estimate the amount of activity or work that will be performed in that same time period. For this example, we’ll say the marketing agency estimates https://www.bookstime.com/articles/purchase-discounts that it will work 2,500 hours in the upcoming year. After reviewing the product cost and consulting with the marketing department, the sales prices were set.

Formula for Predetermined Overhead Rate

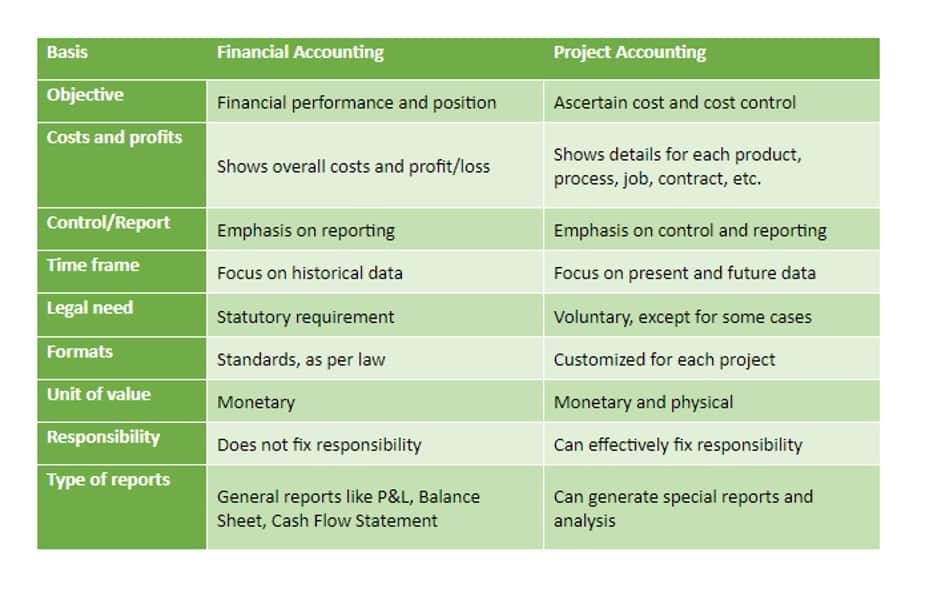

It’s because actual overheads vary from period to period based on seasonal variation and changes in the external environment. Until now, you have learned to apply overhead to production based on a predetermined overhead rate typically using an activity base. An activity base is considered to be a primary driver of overhead costs, and traditionally, direct labor hours or machine hours were used for it.

![]()

Direct Costs vs. the Overhead Rate

- Once you have a good handle on all the costs involved, you can begin to estimate how much these costs will total in the upcoming year.

- Based on the manufacturing process, it is also easy to determine the direct labor cost.

- This allocation process depends on the use of a cost driver, which drives the production activity’s cost.

- The most important step in calculating your predetermined overhead rate is to accurately estimate your overhead costs.

- Estimating overhead costs is difficult because many costs fluctuate significantly from when the overhead allocation rate is established to when its actual application occurs during the production process.

- Not a whole lot compared to other business models (which is probably why a lot of people choose to start these sorts of businesses!).

Finally, you would divide the indirect costs by the allocation measure to achieve how much in overhead costs for every dollar spent on direct labor for the week. You can calculate this rate by dividing the estimated manufacturing overhead costs for the period by the estimated number of units within the allocation base. The production manager has told us that the manufacturing overhead will be $ 500,000 for the whole year and the company expected to spend 20,000 hours on direct labor. The management concern about how to find a predetermined overhead rate for costing.

- Hence, a suitable rate can be estimated based on the forecasted conditions of the accounting period.

- The predetermined overhead rate is used to price new products and to calculate variances in overhead costs.

- The best way to predict your overhead costs is to track these costs on a monthly basis.

- That’s why it’s important to get to know all of the different terminology relating to accounting, and how these financial metrics can be used to assess the financial health of your business.

Component Categories under Traditional Allocation

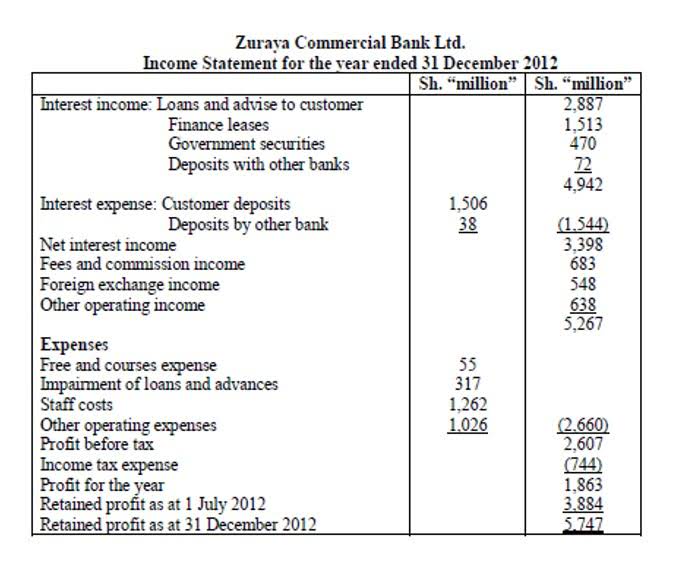

Calculation of Predetermined Overhead and Total Cost under Traditional Allocation